Elizabeth Higgins, CCE ENYCHP

Reprinted with permission from TREE FRUIT NEWS, July 2022, Volume 10, Issue 4. Cornell Cooperative Extension Eastern NY Commercial Horticulture Program

Are you concerned about crop load management on your farm?

Industry has taken note and you may have more tools for making

management decisions in the future. “One of the challenges

expressed by growers is that there still is a lot of manual time

measuring and counting blossoms, fruitlets and apples, which is not only time-consuming, but it is subject to inconsistencies and

different views depending on the staff input,” said Jenny Lemieux,

CEO of Vivid Machines, one of three companies trialing precision

mapping and remote sensing tools this summer in New York. In

addition to Vivid Machines, Farm Vision and Fruit Scout are also

conducting on-farm trials.

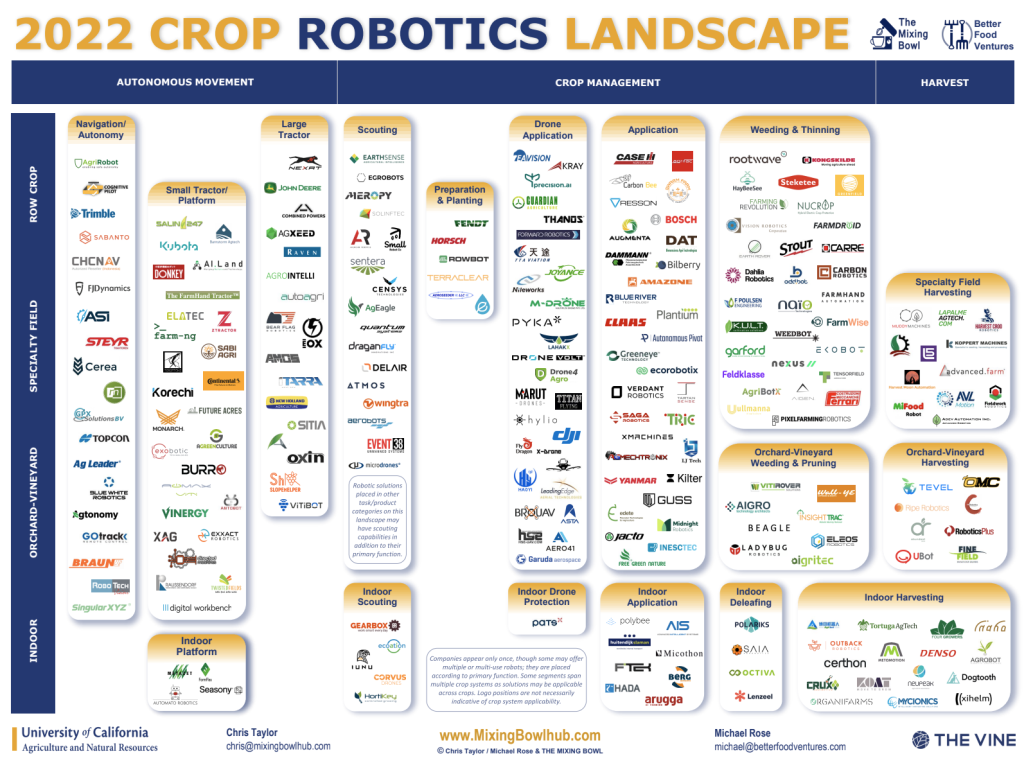

Vivid Machines, founded in Toronto in 2020, has developed a system they call “X-Vision” which captures the quantity and quality of fruit crops from blossom to harvest. The X-Vision system has three components: a high-speed multispectral camera with a vehicle mounted housing system, a camera control and real-time analytics app, and a cloud-based analytics platform. Mounted on a tractor or ATV, the camera captures images as it moves through the row, and the data can be viewed in real time via mobile device. The X-Vision system can get accurate crop counts moving at a speed of up to 7 miles per hour, according to Vivid Machines CEO Jenny Lemieux. The system can examine trees, review blossom clusters, and measure apples, Lemieux said in a company press release. “Growers can see this information and filter the data by variety, block, date, and other factors to get a very granular view of their orchards and how they may change over time.” Vivid’s first paid trials started this season, with six growers in Ontario and New York. According to Produce News United Apple is one of the New York growers in a beta test.

Farm Vision Technologies, founded in Minnesota in 2017, has been testing and refining a handheld crop load management tool for the past few years. It is now commercially available to growers, said CEO and co-founder Patrick Plonski in an article in Good Fruit Grower. The handheld Farm Vision tool contains a Samsung phone with computer vision software, attached to a more sensitive GPS sensor, he said. We view it as the simplest possible system that can get good accuracy.” For thinning decisions, the grower marks off a section of about five trees, or roughly 15 feet long. The grower then faces the canopy, pushes record and moves the camera in an up-and down motion while walking along the row sample. It takes about a minute to get the data needed to use the fruitlet growth model. For estimating harvest yield, the grower faces the camera toward the fruiting wall at about eye level, so the whole tree is in view, pushes record and walks or drives the length of the row. If the unit is mounted on a vehicle, speeds of up to 10 miles per hour work fine, depending on the terrain and vehicle suspension. Anna Wallis of Michigan State and Craig Kahlke of the Lake Ontario Fruit Team are working with Farm Vision Technologies on on-farm trials.

The final company is FruitScout, which launched in 2021 with a

handful of pilot customers and plans a wider rollout later this year

and next. Like Farm Vision Technologies, FruitScout uses a

smartphone with an app. The FruitScout app guides users as they

walk down an orchard row, taking a picture of each tree. How many trees should be sampled to get a representative sample depends on variety. According to the company highly variable Honeycrisp may need 15 percent of the block sampled, while Gala just needs 5 percent, but the company is fine-tuning these recommendations based on field trials according to an article in Good Fruit Grower. From the images collected, the technology counts buds, then blooms, and finally fruitlets to help growers optimize crop load management strategies. Growers set targets in the app, and Fruit Scout’s dashboard tells them how close they are through each step of the season. It also suggests a target fruit count based on the size of the trunk. The Lake Ontario Fruit Team is also working with FruitScout on on-farm trials and FruitScout is currently commercially available to growers.

You can learn more about both Farm Vision and FruitScout at the

Lake Ontario Fruit tour on August 9, 2022 in Orleans County. For

more information and a registration link, go to: lof.cce.cornell.edu/

event.php?id=1669.

Company websites

• Farm Vision Technologies https://www.farm-vision.com/

• Fruit Scout https://fruitscout.ai/

• Vivid Machines https://www.vivid-machines.com/

Recent Articles with More Information

Produce News (May 3, 2022) “Favorable weather, new technologies

open season for United Apple” https://theproducenews.com/apples/

favorable-weather-new-technologies-open-season-united-apple

Tom Karst (May 5, 2022) “With a bigger crop expected this year,

technology aids New York apple grower” The Packer https://

www.thepacker.com/news/packer-tech/bigger-crop-expected-yeartechnology-aids-new-york-apple-grower

Matt Milkovich (March 21, 2022) “A Vision in Hand” Good Fruit

Grower https://www.goodfruit.com/a-vision-in-hand/

Mat Milkovich (March 21, 2022) “Computer eyes” Good Fruit Grower

https://www.goodfruit.com/computer-eyes/

Kate Pregnaman (March 21, 2022) “Phoning in Precision” Good Fruit Grower https://www.goodfruit.com/phoning-in-precision/